EnAIRgy is a specialty finishing machine for value added goods: it’s the ideal tool for those who mean to improve the product market positioning conferring softness, bulkiness and volume, drapery, shrinkage and changes of look such as: aged look, crinkling, millwash, lamb-skin look, spongy look, tridimensional effetcs etc… The range of finishing effects provided by ENAIRGY is comparable to the general range of effects produced by rotary drum tumblers, though in a continuos and open width process.

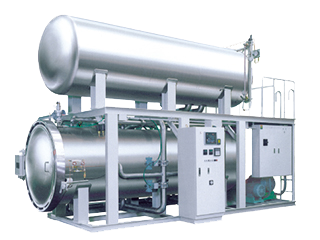

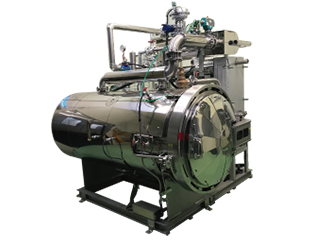

As per its name, EnAIRgy is energy of air and its action gets its maximum creative content in the final finishing step, just before inspection and packing. The dyed goods, printed or coated, are thrown by the air pressure against a stainless steel grid in a variable speed on all working width, reproducing in an industrial way that ancient activity of massage and beating of the old women on the river rocks. ENAIRGY can work on dry goods – thanks to its powerful mechanical action – or on fabrics previously padded with chemicals or simply steamed with free steam in order to increase the spectrum of effects.

Choosing EnAIRgy means deciding to escape from the pure “commodity” segment, from the price battle dynamics, in order to achive an uniqu and distinguished product positioning, without necessarily re-designing the product from yarn to weave and dyeing, eventually changing its look and feel perceptions.

The secret of EnAIRgy is the combination of an alternated discontinuous motion within a continuous process: while infact inside the machine th e stored goods keep smashing at high speed in a back and forth motion, externally the fabric enters and exits continuously without any pause. This is possible thanks to a low speed entering and exiting the equipment (mechanically adjustable from 3 to 25 mt/min) and to a very high speed in the internal back and forth motion (pneumatically produced by the air pressure and adjustable till 2000 mt/min).