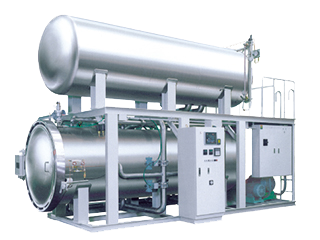

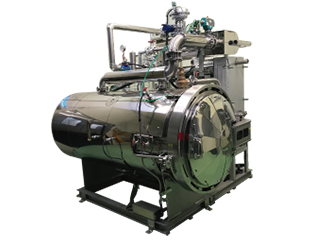

- Hot water spray type retort sterilizer(RCS)

- No variation in temperature, and possible to adapt for air-containing container.

-

The sterilizer has very high temperature uniformity during the process of warming, heating and cooling, and no variation in temperature.

The sterilizer has very high temperature uniformity during the process of warming, heating and cooling, and no variation in temperature.

By performing indirect heating/cooling with a plate type heat exchanger, we prevent contamination from steam and cooling water and safely handle important products.1. Heat sterilization by a four-way spray nozzle with uniform and high dispersion.

A four-way spray nozzle placed on each product tray enables heating and sterilization with the same quality at all up/down, right/left and back/forth tray positions.

The direction of the nozzle is clear, and uniform diffusion of hot water is achieved up to the center of each tray.Ideal system minimizes temperature variation inside the processing tank even in large size equipment

2. Suitable for air-containing containers and glass bottles.

No influence of water pressure due to buoyancy or liquid depth, and even large size equipment can adapt for air-containing containers and glass bottles.

The retort foods in air-containing containers can be sterilized without deforming the container by the air-containing container processing system.3,1. Economical in energy saving and water saving type

The amount of holding water is 1/6 to 1/7 of hot water storage type, and the running cost is reduced by using the cooling tower which is standard in the plate heat exchanger.

The use of a hot water recovery system (optional) in large size equipment enables further energy saving and water saving.3,2. No secondary contamination

Since circulating water is sterilized with a plate heat exchanger, there is no secondary contamination in the cooling process and no pre-treatment of coolant is required by chlorine or the like. Also, there is no need to worry about contamination from heated steam.

4. Can be installed anywhere

No hot water tank is required, and because of its lightweight and compact design, it can be freely laid out such as installing on the second floor. It also improves the working environment by reducing noise levels which is difficult to achieve in direct heating.

Dimension, weight and utility

5. Experienced control technology

Adopting AMMU (Pattern setting instrument) to set and register the planned sterilization conditions for food sterilization (HACCP-compatible). The ideal system to prevent the mistake of the setting operation by calling up the best sterilization condition by the pattern card by one touch, it is possible to correspond from one sterilizer unit to the unmanned operation in the factory (FA System).

Ý kiến của bạn