- Plate heat exchanger for food(FX series)

- Food dedicated plate to solve the problem of food production line

-

Smooth and product-friendly liquid flow through the plate provides uniform heating and quick liquid replacement characteristics.

The electrolytic polishing plate prevents from the scales and burnt, and can be cleaned with CIP.Features

Uniform and smooth liquid flow realizes uniform heating and cooling of products, reducing the amount of holding liquid.

The electrolytic polishing plate reduces the deposition of the scale, allowing long continuous operation.

Improved cleanability by greatly reducing the number of contact points between plates and preventing from the scales and burnt.

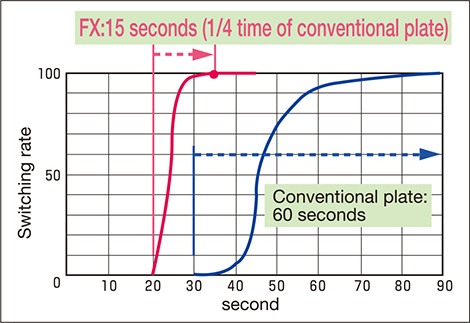

By realizing the piston flow, the liquid replacement time is greatly shortened, and it contributes to the reductions of the operation time and products loss.

Applications

Beverages Bottled water, water, tea, juice, coffee, soda (syrup), milk, cream, condensed milk, jelly, yogurt, mayonnaise, etc. Brewings Soy sauce, noodle soup, sake, cloudy sake, amazake, liqueur, wine, whisky, shochu, etc. Scope of the application

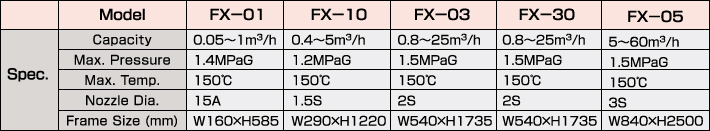

FX series lineup

Note: Please be aware that the dimensions may be changed without notice.

Applicable Material

Plate / SUS316, Titanium

Gasket / EPDM, fluorine resin cushion gasket (TCG), silicon

Development concept

1.Sanitary

1) No remaining scale after CIP

2) Easy to disassemble and wash2.Stable quality and production

1) Ensuring uniform heating history by uniform liquid flow

2) Improvement of liquid replacement efficiency

3) Prevention of scale occurring during Operation3.Economical operation costs

1) Complete recovery of residual liquid

2) Reducing Utility load

3) Ease of operation

4) Highly efficient liquid replacement

5) Reducing installation space

Introducing the test cases of the liquid sterilizers

Various test data

Ý kiến của bạn